The purchase of metals such as stainless steel or aluminum for use in the manufacture of your products is a purchase of great importance. The rolls used to stamp parts for automotive applications can cost from a few thousand to hundreds of thousands of dollars or more. Moreover, the quality of that material and the company from which you buy it can affect the success of that material for your business in various ways.

It is no wonder that the purchase of rolls is an acquisition that should not be taken lightly. For many of you, your ability to successfully achieve your company's key performance indicators when buying steel and aluminum from foundries, service centers, or precision rolling mills will depend on a number of factors, from price to quality. There are also many other influencing factors, such as tolerance and mechanical properties.

When sourcing stainless steel or aluminum, it is important to understand that some metal suppliers and manufacturers, such as steel mills, supply metal to multiple markets, while others prefer to specialize in one or two, whether automotive, construction, or aerospace.

It is easy to underestimate the complexity of buying metals, but when looking at the landscape of metal suppliers one is faced with another tough choice: which of the main service centers or precision metal manufacturers should I choose to source rolls of stainless steel or aluminum?

It is necessary to do a lot of research before buying the material and making a series of decisions.

If you rush in without doing your homework, you could end up overpaying, buying a roll that has quality problems or lacks the proper temper, has a corrosion resistance or mechanical properties that are not optimal, etc.

Doing research can help you make informed decisions about the type of metal you buy and its properties.

Our aim with this article is to help you understand the key elements you should consider when selecting a supplier of stainless steel or aluminum rolls with high corrosion resistance and high malleability, especially for those of you located within the Mexican automotive industry.

If after reading this article you still have questions, please contact us and we will do our best to answer you as completely as possible.

So, what should you look for when evaluating raw material or engineering suppliers? Let's get down to business...

1) Capacity

The first thing to look at is capacity. Is this service center or mill capable of producing the material I need, with the specification I am working with? Are they able to cut the material to the widths you need with the reduced edge you require? Capacity is paramount because if they do not have the ability to produce or supply the material as you need it, there is no possibility of establishing a relationship.

Auto parts manufacturers in North America have different needs in terms of the capacity their suppliers must have to successfully meet. There is a wide range of manufacturers in terms of the level of precision, their alloy processing capabilities and their means to meet thickness, width, tolerance, mechanical properties and temper requirements.

Research and carefully examine the supplier's website and industry directory profiles to learn about their capabilities. Then, contact the top candidates for more information.

When working on the initial quote process with a metal manufacturer, you should make sure to include as many details as possible about the specification and provide as many specific details about your request as possible, including the estimated annual usage. This will help the service center identify if your request is something they can provide.

2) Alloy Selection

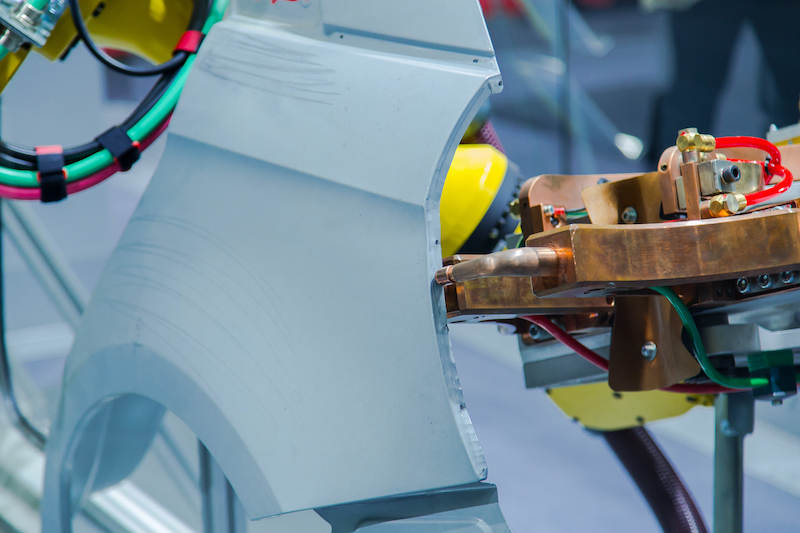

The parts manufactured by stampers and manufacturers that are used to produce components for car engines, airbag systems and sensors are made with a variety of alloys that can withstand demanding conditions such as heat, stress and environmental factors. This type of applications are inheriting demands as a result of innovation. Car engineers and designers are pushing the limits to achieve lighter weight, better performance, increased electrical properties and greater durability. These demands put increasing pressure on the selected alloys and open the door for new alternatives to be required to meet end-use needs.

Auto parts manufacturers, like you, are also taking care of focusing on components that allow vehicles to use fuel more efficiently. In turn, as manufacturers develop and implement their electrification strategies, the need for lighter and stronger materials is at the forefront.

With this trend to seek lighter vehicles, it is necessary to use suitable materials, which benefit the cost and production time. Therefore, vehicle manufacturers are constantly searching for new alloys of maximum quality and precision for their models. Mainly, looking for them to be attractive to their customers and allow them to improve the safety they can offer in each vehicle, avoiding noise, vibrations and reducing fuel consumption. All this, in addition to complying to the letter with environmental regulations, which are increasingly stricter. The lightening of vehicles is the best way and the biggest manufacturing trend of the coming years.

Fortunately, there are several alloys in the commercial offer that have proven their effectiveness in these critical applications. At Ulbrich, buyers can get "just in time" deliveries when required and select from generous inventories covering more than 165 grades of stainless steel, aluminum, nickel alloys, cobalt and titanium alloys and titanium alloys in a range of thicknesses, shapes, sizes and temper. Including sheets and strips in a variety of gauges, as well as wire, round bar, centerless ground bar, hexagonal bar, rod, sheet and plate from other Ulbrich divisions.

3) Compliance

Compliance can be a crucial factor for manufacturers supplying parts to the automotive industry. It is necessary to ensure that the supplier or the rolling mill partner from whom you purchase the material has the necessary certifications to meet your compliance requirements. In the automotive industry sector, there are some important certifications that you can demand from your supply chain partners in order to market a particular part.

Among these regulatory certifications is the IATF 16949, a standard that affects the vehicle manufacturing process and the supply chains that provide materials to car manufacturers. The main objectives of this standard are to prevent waste in the supply and assembly process, avoid manufacturing defects, improve the quality of manufacturing processes and increase the safety and reliability of vehicles. The International Automotive Task Force developed this regulation to coordinate the quality standards of different countries.

If your organization complies with the IATF 16949 standard, it would be preferable to source materials from a service center, or from a precision rolling mill that also complies with the IATF 16949 standard. Ulbrinox, a division of Ulbrich located in the heart of the Mexican automotive industry, has this certification and has supplied stainless steel and aluminum to countless automotive manufacturing companies. IATF certification (or in process) is a requirement for many of the major contract manufacturers supplying parts to major OEMs.

Another commonly required certification is ISO 9001:2015. ISO 9000 is a set of standards that provides objectives to help various companies improve their practices. Several Ulbrich facilities worldwide, including Ulbrinox, have also obtained ISO 9001 certification. The ISO 9000 family of standards includes seven quality management principles: customer orientation, leadership, people commitment, process approach, improvement, evidence-based decision making, and relationship management. The ISO 9001:2015 certification demonstrates that a company complies with the ISO 19000 family of standards in its practices. It allows to demonstrate that a company is committed to excellence and improvement in its relationships with customers.

A certification that has gained increasing importance in recent decades has been ISO 14001. ISO 14001 certification is an important certification for some auto parts manufacturers considered as a show of the company's dedication to environmental responsibility. It is based on a company's compliance with the ISO 14000 series of standards. ISO 14001 demonstrates that a company is working to reduce the negative environmental impact in all its processes and allows companies to establish a more positive relationship with their customers and avoid environmental penalties. Although Ulbrich does not have this certification, we comply with the main requirements of this standard just like the supply chain providers, where we are continuously audited by customers.

4) Quality Control Measures

Quality, reliability and innovation are the driving forces that not only shape the DNA of Ulbrich and Ulbrinox, but describe the responsibility of all manufacturers that make up the stainless steel and aluminum supply chain for the automotive industry.

In order to know that you are working with the right supplier and maintain an uninterrupted supply chain, it is necessary to work with a service center or a rolling company with very advanced quality control.

To ensure speed to market, it is essential to work with a partner that offers the support of metallurgy experts to gain technical insights that can help your team anticipate and avoid problems that arise during the development of new projects. In addition, a team of technical experts plays a major role in providing unparalleled quality control.

Corrugated or scratched material is unviable. The rolls used for automotive applications must be flat, with the right surface finish, temper and edge condition. When researching suppliers, ask them about their ability to achieve material flatness and consistency, and how the metal can guarantee the uniformity of finished products. Quality is one of Ulbrich's core values.

Quality control measures are extremely important for your business and for the ability to keep your machines running. Both your supplier and