The aluminum is one of the most used materials for different products and industries. This is due to its characteristics, which make it an ideal material to withstand all types of temperatures and climates.

It is stable in the air and resistant to corrosion, in addition to presenting an incredible resistance to salt water, as well as for many liquids and various chemical agents. However, there are recommended finishes for aluminum that we should know.

Aluminum industry and finish recommendations

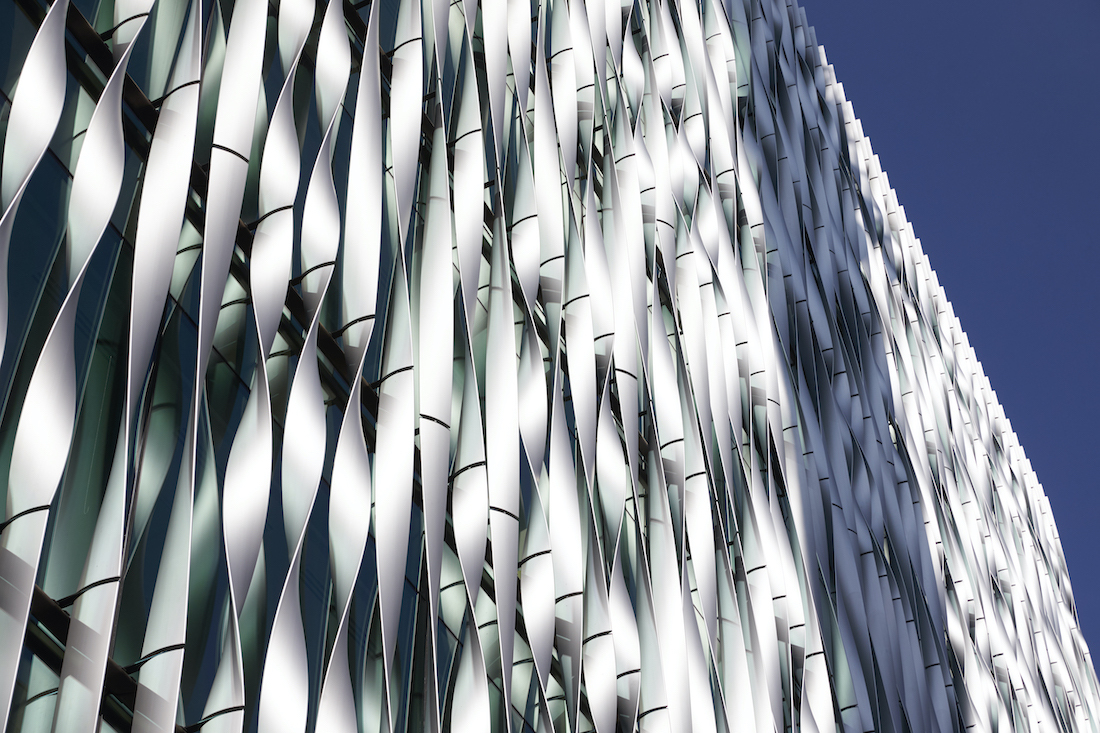

Within the aluminum market there are several types of finishes that can be applied to this type of material. As for the alloy that is used in architecture, it has a very high level of demand.

Where processes of the highest quality are demanded, factors such as corrosion, ease of cleaning, aesthetics and durability must be considered. All with the purpose of creating resistant structures that provide the security that users seek and that is a necessity for this type of application.

When most metals are exposed to the environment, they suffer corrosion. This can vary in severity, but in all cases it affects the aesthetic and mechanical properties of the material, making it weaker and with an unpleasant appearance. For this reason, aluminum stands out from the rest.

Types of finishes that aluminum has according to its texture

Although there are various methods and styles to give a certain appearance to this material. There are two main ways to select the best aluminum finish. These are: by texture and the other by color.

Finishes according to its texture

Anodized Aluminum

Anodizing is the process of thickening the natural oxide layer on the surface of metal parts. In the case of aluminum, an artificial protective layer is generated that increases its resistance and durability.

This is achieved by immersing this alloy in a bath of sulfuric acid and passing a current of approximately 6000 amperes at 20 volts. The mechanical treatment of the surface can be used to achieve a wide variety of textures. From which we can identify three main finishes:

Direct Aluminum

Sanding Texture

Polished Aluminum

Each of these aluminum finishes provide special characteristics that make it ideal for different industries. In addition to providing a more natural or brighter effect depending on the treatment used in this metal.

Lacquering Process

The lacquering of aluminum is done by applying polyester powder paint to the profiles and then polymerizing them in the oven. Applying electronically charged powder paint of the opposite sign on the support.

In this way, a homogeneous layer of this added material is achieved. To finish the process, the type of profile is placed in an oven to melt and polymerize the paint, achieving the hardness and quality that this finish requires.

The lacquer allows a wide catalog of textures, with two types of finishes available:

With glossy or matte finish: The glossy effect is achieved by applying a layer of varnish over the lacquer, while the matte is achieved by removing this added element from the equation.

Textured and matte textured: The effect of the textured is achieved by sprinkling marble powder of various granulometries on the lacquering, resulting in a finish of more or less rough texture. A glossy finish is achieved with varnish, and a matte finish without it.

Finishes according to its color

Anodized: Aluminum can be dyed in a variety of shades thanks to the anodizing method described in the previous section. Salt coloring produces a wide range of shades, including the most popular ones, such as silver, bronze and black, as well as gold, blue, green and red.

Lacquered: The lacquering method allows a wide selection of colors for the two types of finishes: glossy or matte lacquers. These can use any color from the RAL chart, while textured lacquers use colors from the FUTURA chart.

The multiple textures and colors can be used in any installation that an industry may require. Including, all forms of windows, doors, terraces, roof systems, among many other options.

At Ulbrinox we are the most reliable supplier in the metal mechanical industry in Mexico. To achieve the satisfaction of our clients, we have quality policies focused on achieving this goal.

Find out about our services on this website or get a quote! With us you will get the quality and experience your company needs.