Aluminum is the third most abundant element in the earth's crust after oxygen and silicon. The main sectors of use include industries such as transportation, especially air transport. This is followed by its use for cans, pipes, containers, electrical cables, bridges, specialized equipment, etc.

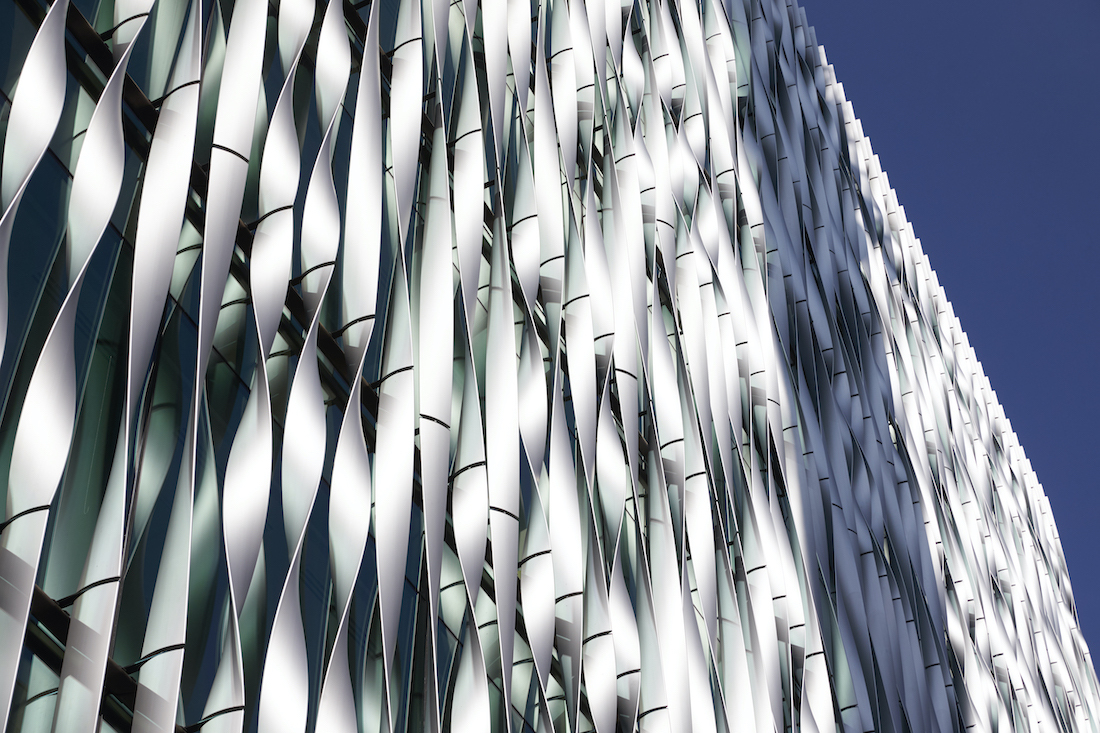

It is also very present in the construction industry, from windows to mobile homes. Thanks to all these uses and characteristics, it was considered for decades more valuable than gold.

The different alloys of this light but resistant material allow us to use it in moderately aggressive environments, such as in the kitchen, where it is used in pots, pans and coffee makers without leaving an aftertaste in the food.

If we compare 2.70 kg of aluminum, it will be equivalent to around:

- 7.9 kg of steel

- 8.93 kg of copper

The yield strength of aluminum is practically lower than that of steel. However, this disadvantage is offset by a lower density, maintaining a lower weight than other metals.

Different aluminum alloys

Aluminum series 1000

Composed of 99% pure aluminum. It is mainly used for chemical plants, heat exchanges, electrical conductors and architectural and decorative applications.

Its main characteristics are:

- Excellent corrosion resistance

- High thermal and electrical conductivity

- Good workability

Aluminum series 2000

Known as Avional. It has been used for decades in the aeronautical industry for the construction of structural elements of airplanes. It is also present in precision tools.

Some of its characteristics are:

- Lightness

- Hardness

- Low corrosion resistance

- Good mechanical characteristics

Aluminum series 3000

The main element of this alloy is manganese. It increases the mechanical strength of the series, but has less ductility. It is used for kitchen utensils, containers and pressure pipes.

Aluminum series 4000

Silicon is the main alloying element of this series, which provides good wear resistance. Other alloying elements can also be added, such as copper and magnesium.

Aluminum series 5000

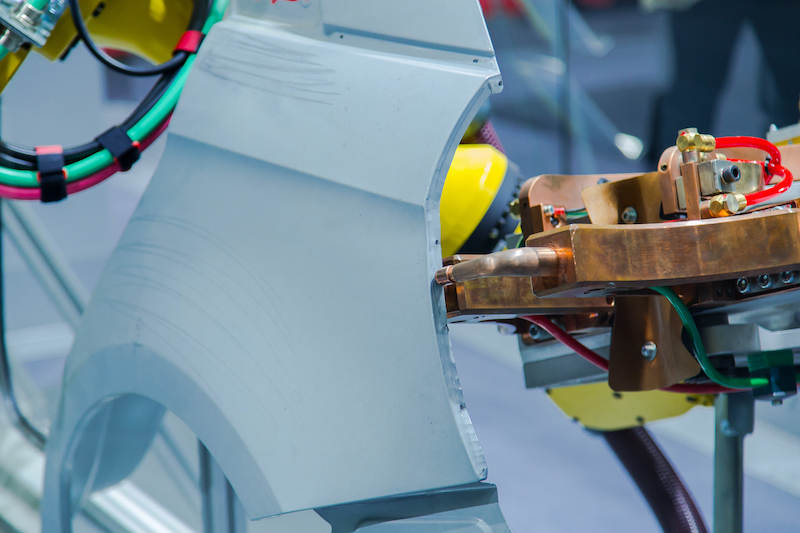

Known as Peraluman. The main element of this alloy is magnesium, after heat treatment they develop intermediate mechanical characteristics. It is used to work in the marine environment and in the automotive industry for the construction of bodywork.

Some characteristics of this series are:

- Mechanical characteristics

- Resistance to corrosion and melting

- Ideal for welding

Aluminum series 6000

Also known as Anticorodal. The main elements of this alloy are silicon and magnesium. It is used in frames for motorcycles, bicycles and generally welded structures.

Some of its main characteristics are:

- Good mechanical resistance

- Good formability

- Good level of manageability

- Cutting capacity

- Welding capacity

- Corrosion resistance

Aluminum series 7000

Commercially known as Ergal, the main element of this series is Zinc, with possible additions of magnesium. This alloy is used when lightness is required from aluminum, such as in aeronautical structures and means of transport, especially in the motorcycle sector and in bicycle frames.

Corrosion resistance

- Good manageability

- Fusion weldability

Learn about the Aluminum alloys we offer at Ulbrinox for your supply chain management system.