The metal bending process is a widely used technique in the manufacture of parts and components for different industries. This process allows shaping sheets of an alloy to adapt them to different uses and applications. In this article, we will explore in detail this work method, its main techniques, and considerations.

What is metal bending?

The metal bending is a deformation process in which a metal sheet is subjected to a force that makes it bend or curve. The main objective of this process is to obtain a piece with the desired shape and dimensions, which can be achieved through different techniques.

Metal bending techniques

There are different metal bending techniques, each of which is used for different applications and types of pieces. Some of the most common techniques are the following:

Roll bending: this is a roller technique ideal for bending metal sheets. It is used for thick alloys and is performed on three or four roller machines. The metal is fed between them, which apply a force to give the desired shape.

Press process: the press metal bending is a technique that relies on a hydraulic or mechanical press to shape the sheets. In this process, the alloy is placed on a mold with the desired shape and a force is applied. This technique is used for medium-thickness elements and can be performed on machines with one or several stations.

By folding: this is a technique used to bend thin metal sheets. In this process, a folding tool is responsible for bending the alloy into the desired shape. This technique is mainly used for the manufacture of electronic and precision components.

Considerations in the metal bending process

The metal bending process requires a series of considerations to ensure that the desired shape and dimensions are obtained in the final piece. Some of the most important considerations are the following:

Bending elasticity: this is an important property of metals that stands out in the process. It refers to the ability of the metal to recover its original shape after having been put in this process. In general, harder and more resistant metals have a lower bending elasticity, which means they maintain the shape for a longer time.

Minimum bending radius: It refers to the smallest radius that can be achieved in a curved piece without damaging the metal. This depends on the thickness of the sheet and the type of process being used. In general, the thinner the metal, the smaller the minimum bending radius that can be achieved.

Applications of metal bending

The metal bending has a wide variety of applications in different industries. Some of the most common applications include the following:

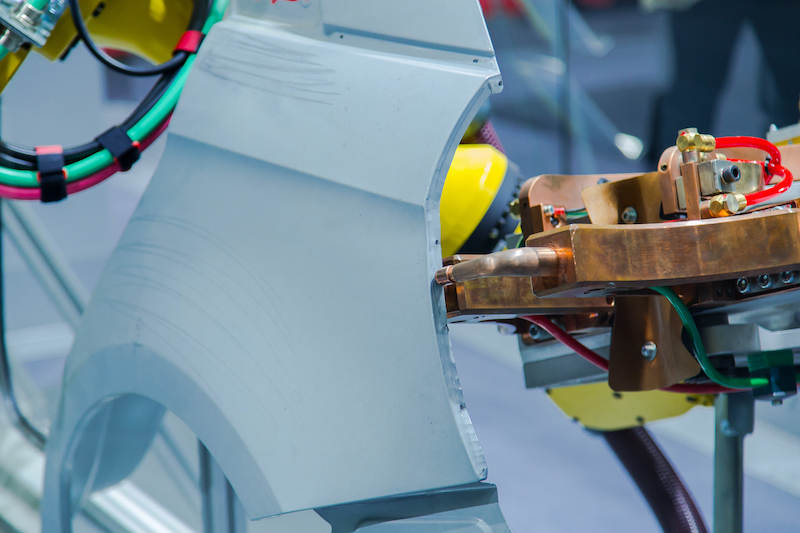

Manufacturing of automobile parts

The metal bending is widely used in the automotive sector. Mainly in the manufacturing processes of parts such as body panels and exhaust pipes. This technique allows obtaining complex and precise shapes that are essential for the manufacture of high-quality components in the automotive industry.

Construction of steel structures

It is also used in the construction of steel structures, such as bridges and buildings. This technique allows creating unique shapes and curves in steel structures that can improve both their aesthetic appearance and their functionality.

Manufacturing of electronic products

The metal bending is used in the manufacture of electronic products, such as mobile phones and tablets. This technique allows producing unique shapes and designs in electronic components that can improve both their aesthetics and functionality.

Furniture manufacturing

Another common use of this process is in the manufacture of furniture, such as chairs and tables. This technique allows obtaining unique shapes and curves that can improve both their aesthetic appearance and their functionality.

In conclusion, the metal bending is an essential technique in the manufacture of metal parts and components. This process allows obtaining complex and precise shapes in sheets of different alloys to adapt them to different uses and applications. Get to know our product catalog or request a quote on this website! At Ulbrinox you have the quality your company needs.