The aluminum profile in modern industry is one of the most versatile and essential components. Its wide range of applications spans from construction to machinery manufacturing. In this article, we will analyze what this element is like, highlighting its characteristics, benefits, and various applications.

Aluminum Profile in Industry: An Overview

This element is an extruded piece that is created from aluminum ingots. This extrusion process allows the creation of profiles with various shapes and specific cross-sections. Over the decades, aluminum has proven to be an ideal material for the manufacture of industrial profiles due to its unique properties such as:

Lightness: Aluminum is a lightweight metal, approximately a third of the weight of steel, which facilitates its handling and transport.

Corrosion Resistance: The natural oxide layer that forms on the surface of aluminum protects it from corrosion, making it suitable for applications in wet and corrosive environments.

Thermal and Electrical Conductivity: Aluminum is a good conductor of heat and electricity, making it an essential material in the manufacture of electrical components and cooling systems.

Malleability: Aluminum is highly malleable and can be formed into a variety of shapes, making it versatile for a wide range of applications.

Applications in the Construction Industry

One of the sectors where the aluminum profile in the industry is used is construction. Its ability to combine with other materials and its versatility make it a standout option for the industry.

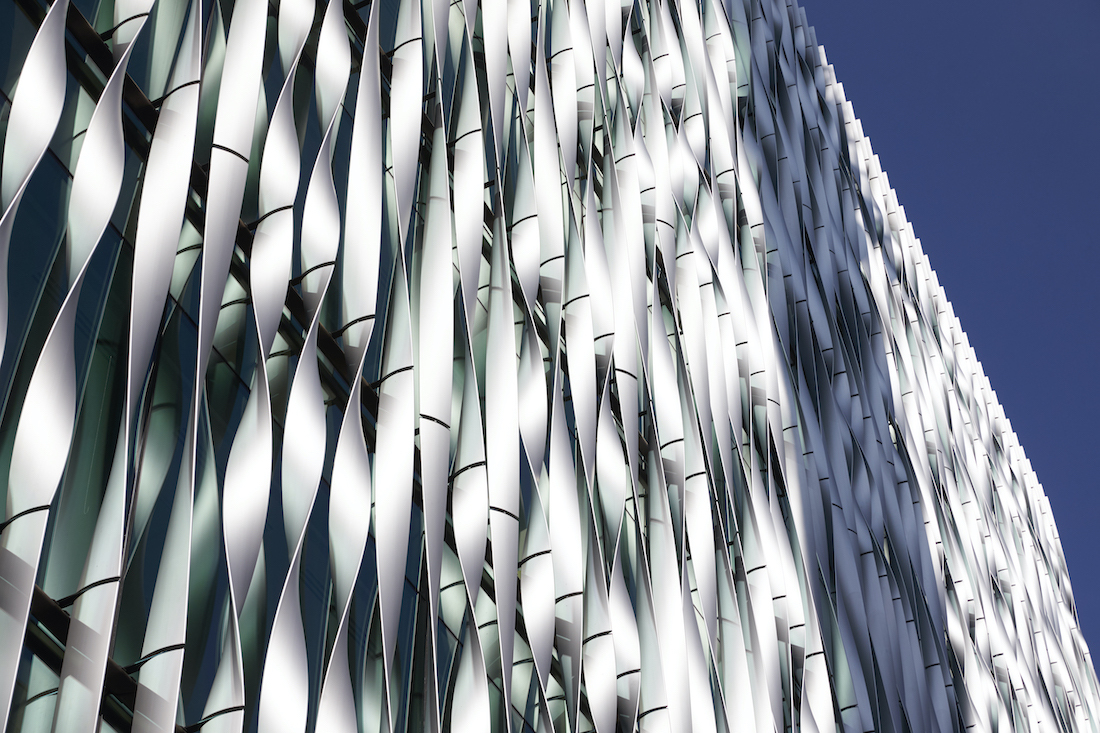

Profiles for Frames and Structures: The aluminum profile is commonly used in the construction of window and door frames, as well as in the creation of building structures, such as canopies and facade systems. Its lightness facilitates installation and its corrosion resistance guarantees a long lifespan.

Railing and Handrail Systems: Railing and handrail systems are essential components in commercial and residential buildings. Aluminum profiles are ideal for these applications due to their combination of strength and aesthetics. In addition, they can be customized to fit different architectural styles.

Metal Carpentry and Space Partitions: In metal carpentry and the creation of interior space partitions, the aluminum profile is used to manufacture structures such as sliding door frames, office partitions, and storage systems. Its versatility allows adaptation to a variety of designs and functional requirements.

Customization and Sustainability Advantages

One of the key advantages of the aluminum profile in the industry is its ability to be customized. It can be cut, machined, and treated in various ways to meet specific design and functionality requirements. In addition, this alloy is a sustainable material, as it is 100% recyclable and can be reused over and over again without losing its properties.

However, despite all its advantages, the aluminum profile also faces challenges in the industry, such as the initial cost and the need for efficient recycling processes.

In conclusion, the aluminum profile in the industry is an essential component, with a wide variety of applications. Its lightness, strength, and versatility make it an invaluable material for the creation of efficient and functional products and structures. As technology and innovation continue to advance, we are likely to see even more exciting applications in the future. This versatile material will continue to play a crucial role in creating a more efficient and sustainable world in all sectors and companies where it is applied.

At Ulbrinox, we provide stainless steel and aluminum products to the metallurgical industry since 1997. We have expert personnel in the sector who are always at your disposal to provide you with the best service and find the right solution for your company. Don't wait any longer and request a quote on this website!