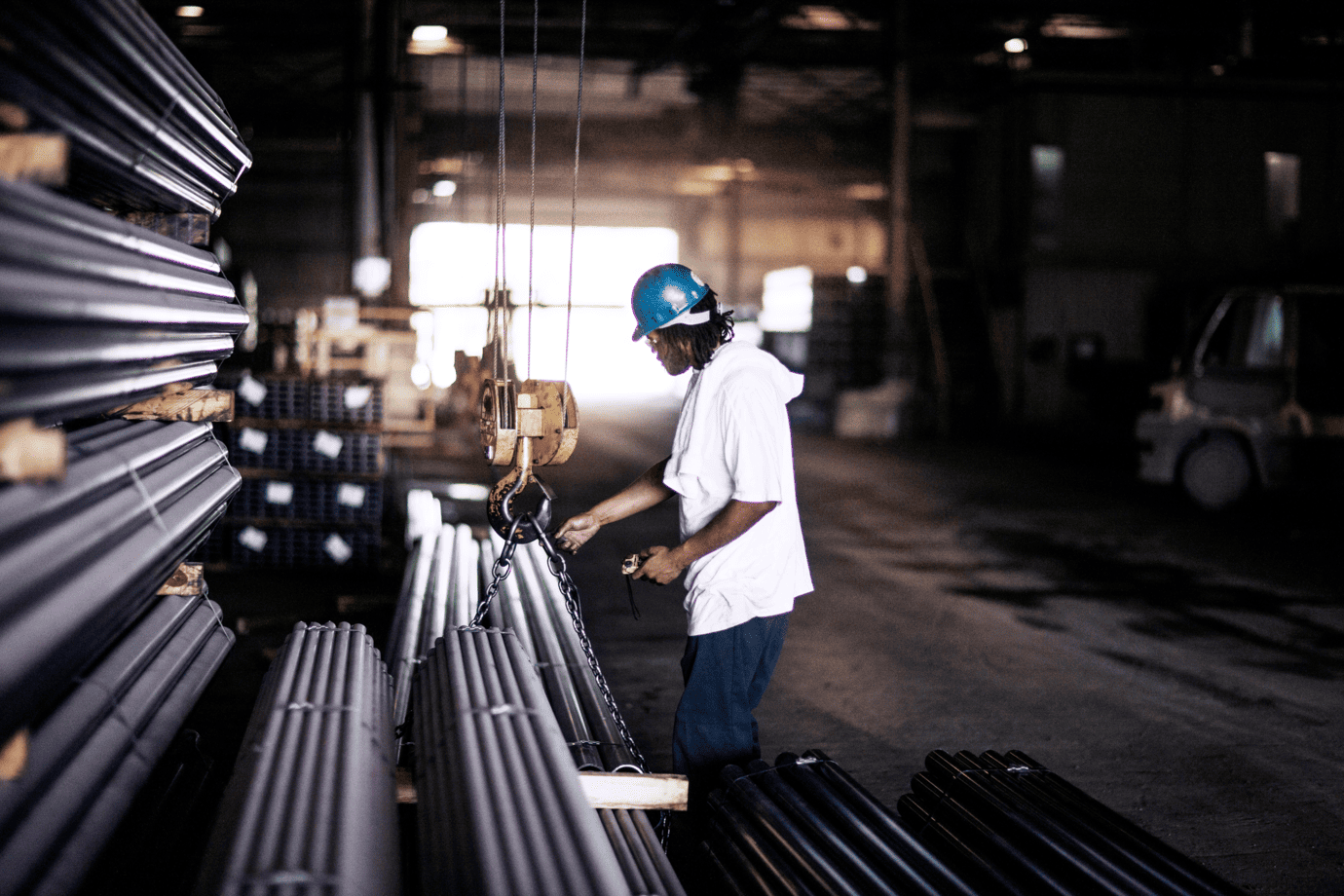

Detailed Specifications & Performance Data

For engineers, buyers, and specifiers who need deeper insight into performance, this technical center brings together all the critical data in one place. Choose the category you're interested in—whether it's alloy chemistry, corrosion behavior, or mechanical performance—and explore verified data that meets the industry's most rigorous standards.