The metal industry is one of the oldest in existence. Several countries determine the growth of their industry by the increase in metals, demonstrating the crucial nature of this material. The metal supply chain consists of three critical stages: smelting factories, rerolling mills, and service centers. Of course, there are other steps in the supply chain and different levels beyond these three. However, for the purposes of this article and the procurement of material for manufacturing processes such as stamping or deep drawing, let's consider these as "the big three".

The melt mill, precision rerolling, and service center all have specific and vital functions they perform in the manufacturing of stainless steel and specialty metals.

All metal items begin the supply chain journey at smelting plants. From the smelting plant, the material is usually sent to service centers or rerolling mills. This often depends on the type of material, thickness, and application of that material. This metal may go through many more levels of the supply chain, such as parts manufacturers or stampers, before reaching the end user.

Most industry players consider rerolling mills and service centers to be even points, but this is not always the case. In this article, we will discuss all stages of the stainless steel supply chain, its importance, and how they meet manufacturers' needs. Part of this information can be applied to specialty metals and the supply chain of those alloys, but we will leave the differences for another article. In this article, we will focus on stainless steel. We will try to inform about the role of each of the three stages and when it is convenient to buy from each of them.

Smelting Mills

Also known as a steel mill or even a steel plant, the steel mill plays an important role in the stainless steel supply chain. Here, new and recycled metallic materials are melted to form stainless steel strips or other shapes such as bars, plates, and wires. Smelting factories collect and process a combination of recycled and virgin stainless steel material to obtain different grades of steel. Normally, the composition is 90% recycled steel and 10% virgin steel. This applies to both stainless materials and carbon steel.

The recycled material can come from various sources, such as normal consumer stainless steel products that are recycled, and scrap from distributors and sellers. Scrap sellers work with precision rerolling mills, service centers, and parts manufacturers to buy and sort "precision scrap", which is already sorted by alloy and avoids metal impurities. Scrap sellers sell this material to smelting factories, where it is checked and sorted again before being melted together with virgin material to create the metal products we know, such as strips, wires, and bars.

Most factories use EAFs (Electric Arc Furnaces), which are more environmentally friendly than traditional blast furnaces. This alternative consumes less energy and produces significantly lower carbon emissions. In addition, stainless steel industry companies strive to minimize waste as much as possible. They collect and separate the product scraps that are usually discarded during manufacturing. All this internal scrap will later be melted in the electric furnace.

The different furnaces used in foundries are responsible for melting the steel. The metal's chemistry is also adjusted by reducing various alloy elements and introducing others to achieve optimal chemical purity. Thin plate foundries from a hot steel mill convert the molten steel into a continuous steel strip about 60 millimeters thick. This strip can be rolled into huge sheets or steel plates efficiently, economically, and quickly. The metal can also be transformed into wires, tubes, and other shapes.

The slabs pass through cooling water to make them completely solid and are reduced to the customer's requirements in a hot rolling mill. Then, the new hot steel strip is automatically rolled up and the coils are chemically cleaned in the cold rolling complex.

In particular, the material coming out of this section may be in strip form, but it is usually thicker and with less strict tolerances. This makes the material unusable for a number of specialized applications in sectors such as medical and aerospace. This is where the fundamental role of a stainless steel rerolling mill comes into play, creating varieties of steel with distinctive characteristics for specific sectors or uses.

For manufacturers looking to buy metal, the option to work directly with the foundry may be an option if they buy a large amount of material with few specification requirements, and also have the ability to keep a large amount of material on the premises at once. In addition, a company with flexibility in its delivery time needs or that agrees with shorter credit terms could consider working with a smelting mill directly as their metal supplier.

Stainless Steel Rerolling

Stainless steel rerolling plays a crucial role in the steel supply chain. As the name suggests, the process involves rerolling the metal to produce material with finer gauges and stricter tolerances, after it arrives at them from a melt mill. The process is usually necessary for the metal used to produce high-end medical and aerospace applications, among others. The demands on the metal may be due to the life-threatening situations in which these applications are used, or the environments to which the metal may be exposed during its final use. If something is going to enter your body (medical needle), you will want a product of the highest possible quality.

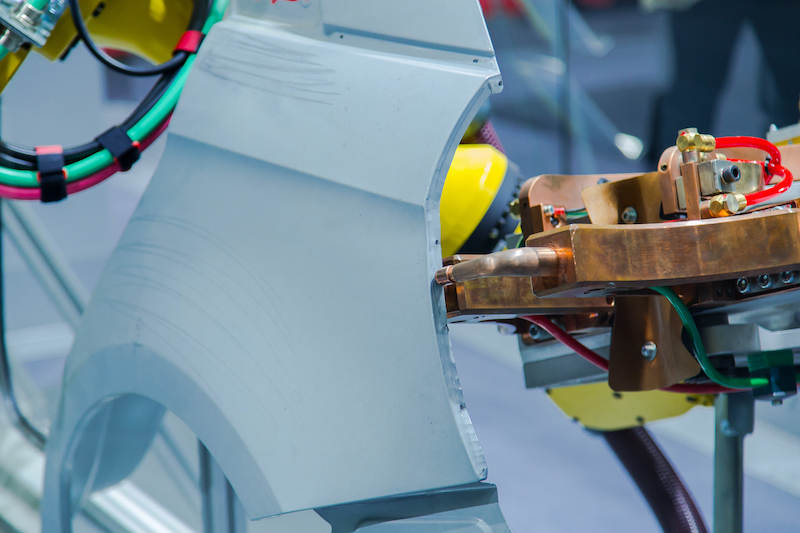

Like the melt mill, a furnace is also used in the rerolling business. The material enters the rerolling train in strip form and must be rerolled to achieve thinner thicknesses. However, due to the mechanical properties of stainless steel, this cannot be done in one go, for most thicknesses. Intermediate annealing (heating) is necessary between rolling sessions to relieve stresses before proceeding to roll to very fine gauges. The rest of the rolling process is usually carried out at room temperature. This is cold rolling. Throughout all these processes, state-of-the-art equipment and systems are used to control and measure the exact thickness of the material throughout the entire coil. This is how precision rerolling mills like Ulbrich can achieve such tight tolerances on their metal.

Metal rerolling is a crucial segment of the steel supply chain and is among the most important combinations of metallurgical knowledge, technology, and processes deployed throughout the manufacturing of stainless steel.

The cold rolling process removes defects from the metal, such as shrinkage, and the material ends up acquiring a compact structure and excellent mechanical and physical properties, with tight tolerances throughout the finished product. The characteristics that precision rerolling is capable of adding to a material make it an excellent option for customers who value (or even demand) consistency and precision in a metal's properties or tolerances.

Manufacturers should consider buying from a precision rerolling mill when the metal for their application has special requirements that cannot be met by a service center. Rerolling mills are fundamental partners for manufacturers engaged in product development. The combination of experience and capabilities offered by a rerolling mill like Ulbrich is of great value to companies that have an application in mind, but parts manufacturers are unsure of which metal or thickness to choose. A rerolling mill like Ulbrich will deploy its team of engineers and metallurgists to help your team overcome metal manufacturing and other challenges that are uniquely suited to your manufacturing processes and application.

Steel Service Center

Another crucial role in the steel supply chain is the stainless steel service center. A service center deals with a wide variety of steel coming from smelting plants or rerolling mills. The facilities have huge storage deposits to ensure the regular supply of their production lines.

Once the material is received, minimal changes are made before reselling it to customers. Some of the activities carried out here can include adding a different edge or cutting the material into various widths, but the thickness remains unadjusted.

The activities that can be performed at a service center, apart from storage, include flattening the material and side cutting, which essentially involves cutting the edges with shears to achieve a standard width. It can also be cut widthwise to form steel sheets or lengthwise. Sometimes all these operations are combined to ensure the customer gets the product they need.

Also, the service center can inspect, repair, and recondition coils. They can also take samples and perform automatic and manual checks throughout the manufacturing chain. The checks are usually unique to each of the customer's orders.

The packaging of the material is not standard and varies according to the customer's needs. It is also common to find service centers that offer storage and shipping services.

Some service centers don't even touch the material. They source hard-to-find material for their customers at a lower price due to the large quantity they purchase and then store and ship this material to customers when they need it. In essence, stainless steel service centers specialize in supply chain management. In this way, service centers greatly help manufacturers manage their inventory levels and keep certain costs lower, while guaranteeing them a stable supply chain. Therefore, it would make sense to buy from a service center in circumstances where material may be needed quickly but a lot of inventory cannot be kept. A service center like Ulbrich's divisions will work closely with you to store the material and ship it as you need it. The material may not be as special as that provided by a rerolling mill, but service centers still have the ability to meet specifications and requirements.

Highlights

The stainless steel supply chain comprises smelting factories, rerolling mills, and service centers. They all have a place and a crucial role and can sometimes be interdependent. Rerolling mills have their own needs they meet, and service centers also fulfill their own function.

Depending on your needs, you can choose to buy from either one. It's important to consider your end application and requirements and decide which one can best meet your needs. Buying from a smelting mill would mean you need massive quantities and not much in terms of specifications and requirements. When considering a service center, it may be convenient to think about whether you need help managing the supply chain or inventory levels and ensuring a stable supply chain. Rerolling mills would provide the most specialized materials. For those special alloys and tight tolerances for specific applications, a rerolling mill could be the ideal choice.

You can count on Ulbrich Stainless Steels & Special Metals, Inc. for excellent quality metals that suit your needs and projects. We are leaders in the precision metals industry and offer a wide assortment of stainless steel solutions used by different companies, from construction to the healthcare sector.

Contact us today to learn about our products or get expert answers from our metallurgists to any question that may arise.

At Ulbrinox we understand the importance of metal in different industries, which is why we are one of the main distributors of these materials in Mexico and Latin America. Come to the experts! We provide the best materials and the highest quality in the product you need. Get a quote on our website or contact us on our online chat for more information.