The automotive industry has undergone a significant transformation in recent decades, largely driven by technological advances and a growing demand for more efficient and durable vehicles.

One of the key elements that has contributed to this change is the use of stainless steel materials, which has emerged as a prominent player.

Today we will explore together how stainless steel materials are redefining standards in car manufacturing, providing benefits that go beyond aesthetics.

The Evolution of Materials in the Automotive Industry

The history of car manufacturing is marked by the constant search for stronger, lighter and more environmentally friendly materials. In this context, stainless steel has emerged as a versatile and sustainable solution.

Its corrosion resistance, durability and ability to withstand extreme conditions make it an ideal candidate for a variety of applications in the automotive industry.

Year | Material | Main Characteristics | Main Applications |

1885 | Iron | Resistant, but heavy and prone to corrosion | Frame, body, chassis |

1910 | Lightweight | Engines, suspension parts, body components | |

1930 | Stainless steel | Corrosion resistant, durable and lightweight | Exhaust components, fuel systems, body components |

1950 | Fiberglass | Lightweight and corrosion resistant | Body components, interior panels |

1970 | Plastics | Lightweight, economical and easy to mold | Body components, interiors, fuel systems |

1990 | Carbon fiber composites | Extremely lightweight and resistant | Structural components, body parts |

In 2023, stainless steel remains the most popular material for a variety of applications in the automotive industry, due to its corrosion resistance, durability and ability to withstand extreme conditions.

Key Advantages of Stainless Steel Materials

Corrosion Resistance: Stainless steel is known for its exceptional corrosion resistance, a crucial property in environments where vehicles are exposed to the weather and adverse climatic conditions. This factor significantly contributes to the longevity of automotive components, reducing maintenance costs and increasing reliability.

Durability and Mechanical Resistance: Stainless steel materials offer a unique combination of durability and mechanical resistance. This translates into a greater ability to withstand heavy loads and resist impacts, resulting in more robust and safe vehicles.

Aesthetics and Premium Finish: In addition to its technical performance, stainless steel adds a touch of elegance and modernity to vehicle design. Its shiny finish and its ability to remain free of stains and wear marks make it an aesthetic choice for high-end car manufacturers.

In exploring the advantages of stainless steel materials, Ulbrinox reveals itself as a key element in the evolution of the automotive industry. To delve into how we drive excellence in these materials, we invite you to visit our page dedicated to the automotive industry. Here, you will find detailed information about its commitment to quality and its essential contribution to the automotive sector.

Stainless Steel for Car Manufacturing

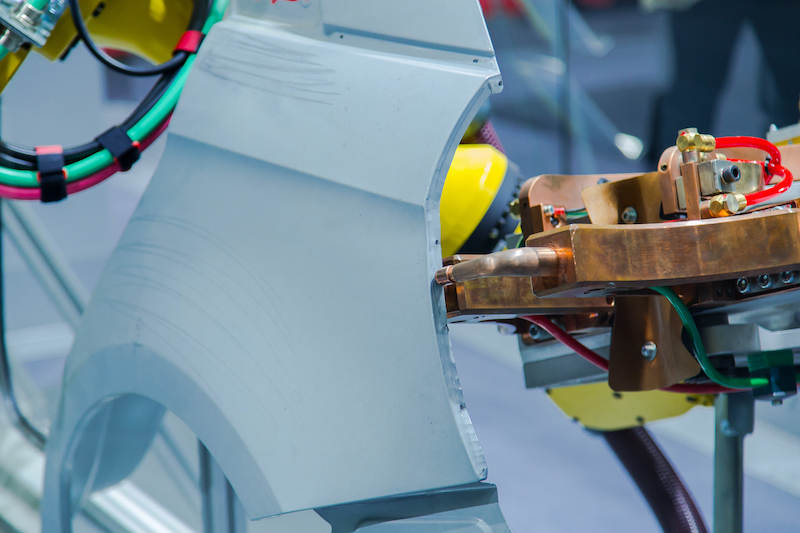

The use of stainless steel materials in the automotive industry extends to a variety of components, from bodies to exhaust systems. Here are some key areas where these materials are making a significant difference:

Body and Chassis: The corrosion resistance of stainless steel is critical for the durability of a vehicle's body and chassis. In addition, its ability to resist impacts contributes to the safety of the occupants.

Exhaust Systems: Exhaust systems made with stainless steel are more durable and resistant to the high temperatures and corrosive conditions associated with gas expulsion. This translates into a longer lifespan and consistent system performance.

Internal Components: From bolts and nuts to more complex internal components, stainless steel is used in a variety of applications to ensure the strength and durability of a vehicle's essential elements.

Contribution to Sustainability

Stainless steel is a highly recyclable material, with a global recycling rate of around 80%. This means that most of the stainless steel used in car manufacturing can be reused to make new products, thus reducing the need to extract new resources.

Specifically, stainless steel contributes to the sustainability of the automotive industry in the following ways:

Reduces waste: Recycling stainless steel prevents waste from ending up in landfills or being incinerated, which generates pollution.

Reduces carbon footprint: The production of stainless steel requires energy and resources, so recycling helps conserve these resources and reduce greenhouse gas emissions.

Extends the lifespan of vehicles: Stainless steel is a durable material that can withstand the extreme conditions of driving. This can help extend the lifespan of vehicles, reducing the need to manufacture new vehicles.

As the automotive industry continues to advance towards sustainability, stainless steel will continue to be an important choice for car manufacturers.

The Future of Stainless Steel in the Automotive Industry

In conclusion, stainless steel materials are playing a crucial role in redefining the automotive industry. From their corrosion resistance to their contribution to sustainability, these materials offer a unique combination of properties that benefit both manufacturers and consumers.

At Ulbrinox we position ourselves as a key partner in the evolution of the automotive industry towards high-quality materials. Our commitment to excellence in the supply of stainless steel and aluminum, backed by metal cutting, forming and machining services, contributes to the creation of stronger, safer and more efficient vehicles.

Discover our wide variety of aluminum and stainless steel alloys that adapt to various applications and industries.